Urban Timber: Capitalizing on a Tree-mendous Resource

A lot has been written in this newsletter about trees in our communities when alive. But these trees can have a second life once they are removed—as a dinner table, artisan bowl, or other special creation. Unfortunately, most trees removed in our communities instead end up in landfills or, at best, are chipped or sold as firewood. The U.S. Forest Service estimates that enough urban wood is generated each year that, if sawn into boards, would produce 3.8 billion board feet of lumber, or nearly 30% of the annual U.S. hardwood production.

When Steve Cashman, a transplant to Star from the Midwest and a hobby woodworker, looked for hardwood lumber in southwestern Idaho last year, he found it a lot more expensive because it came from so far away. At the same time, he observed hardwood trees of the species he was seeking being removed in the cities around him.

Being cheap, as he told me, he started calling and e-mailing tree services, mills, and others to see how he could find and buy this local wood, but with no luck. By the time he contacted me last December, his original intent had transitioned into something much bolder. “I see a great resource being wasted,” Steve explained. “Why pay a lot of money to import hardwood when we have it right here? We have a valuable resource that can be grown, harvested, processed and crafted locally, becoming beautiful and functional products. Plus, carbon is stored long-term, new jobs are created and landfill space is freed up. The end product also has a backstory; the wood that panels a corporate office could come from the trees removed during construction, or a coffee table might be built from a tree planted by the owner’s great-grandparents, or from one that grew down the street.” After I talked with Steve, made some connections and provided some resources, Steve started that “big log” rolling.

The path hasn’t been easy. Steve owns a small data protection consulting business, so none of this is within his wheelhouse. He spent hundreds of hours learning about the entire process, including cutting, transporting, milling, throughout the Treasure Valley, but has so far found only one willing to help out. “Joshua Chavco (Chavco Tree and Landscape) has been great to work with,” Steve told me. “He understands and supports what we’re trying to accomplish and calls whenever he has a tree he’s removing that has potential.” As well, Boise City Forestry sells logs to the public from trees they’ve removed, so this has been another source. Another key partner is Mark Tucker (Tuckers Timber). He’ll drop off a trailer at the removal site so the logs can be loaded onto to it. He takes the logs back to his small mill and cuts them into slabs or boards. Steve then takes the boards home to air dry, store and sell.

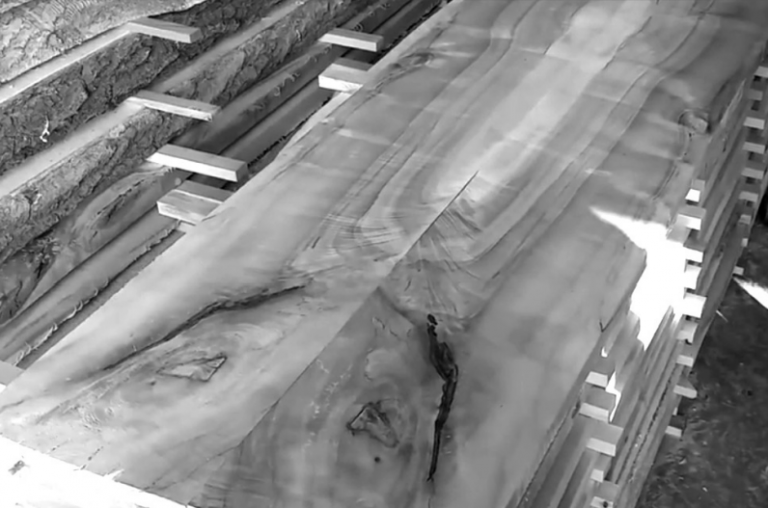

So far, this nascent enterprise has produced about 1,000 board feet of beautiful live-edge slabs, boards and incredible burls for turning. Species include ash, walnut, gingko, maple, black locust, basswood and elm. As a woodworker myself, the photos on Steve’s Facebook page (www.facebook.com/208UrbanTimber) make my mouth water. It’s fantastic material.

I asked Steve what he hoped to accomplish over the next year. He told me, “I really want to grow the network – arborists, local artisans, architects, homebuilders and more – and demonstrably increase the supply of available wood. I’m not doing this to make money (eventually he plans to create a non-profit). I’m selling the wood at a price that covers costs with some to reinvest into improving the system so that prices can be kept low.”

As well, he would love for more tree services and cities to become partners. He added, “I know it takes less time to just chunk the trees up and take them to the landfill, but I hope the idea of reducing waste and atmospheric carbon, adding value and saving money in landfill fees will entice folks to be part of this effort. Steve welcomes feedback on how he can make the process as easy as possible for them.

If you’d like to be involved in any step of the process, from sourcing trees to buying the lumber, please contact Steve via his Facebook page.